Description

- Toecap: 200J polymeric composite non-thermic

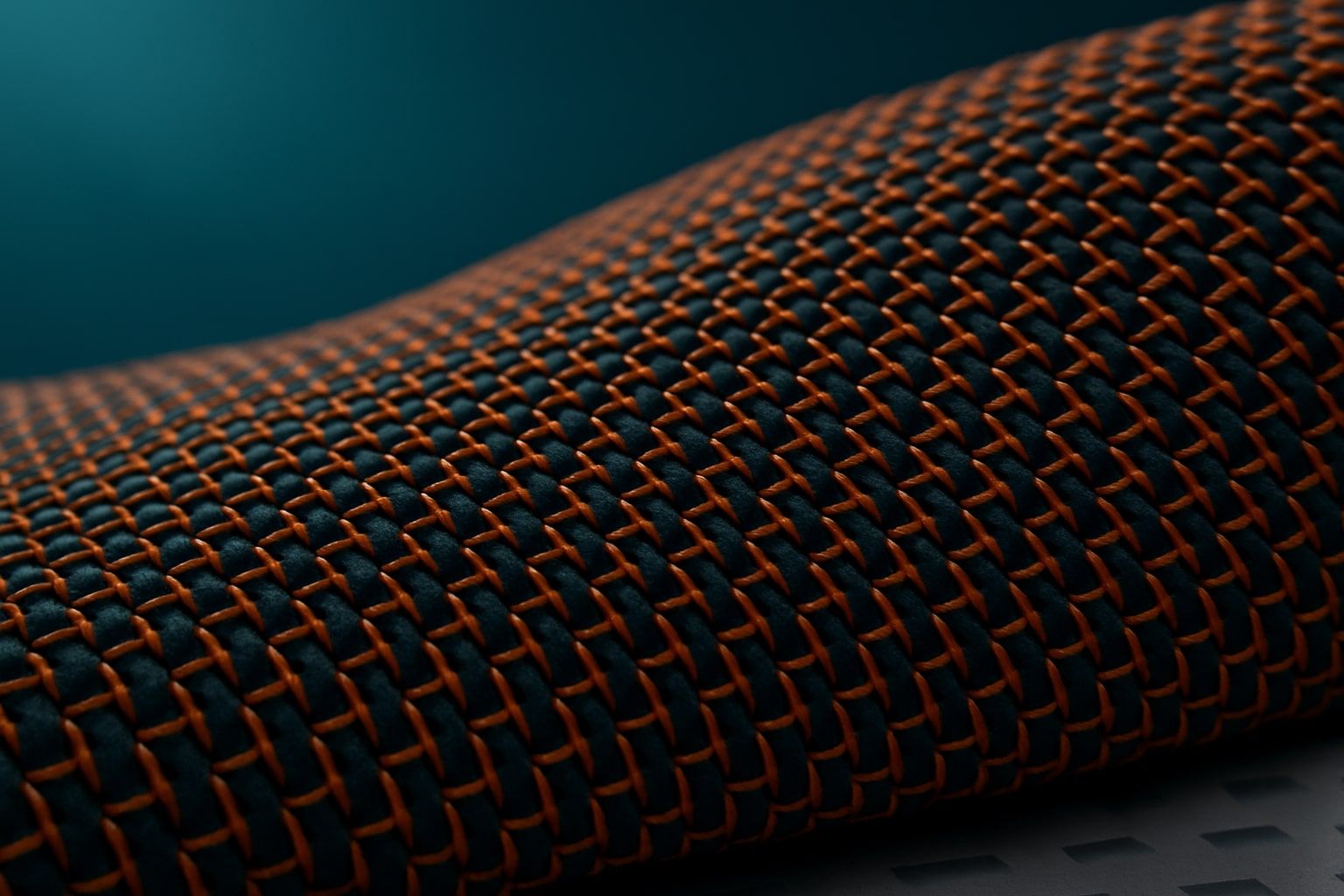

- Upper: Microfiber Microwash 1,8-2,0 mm

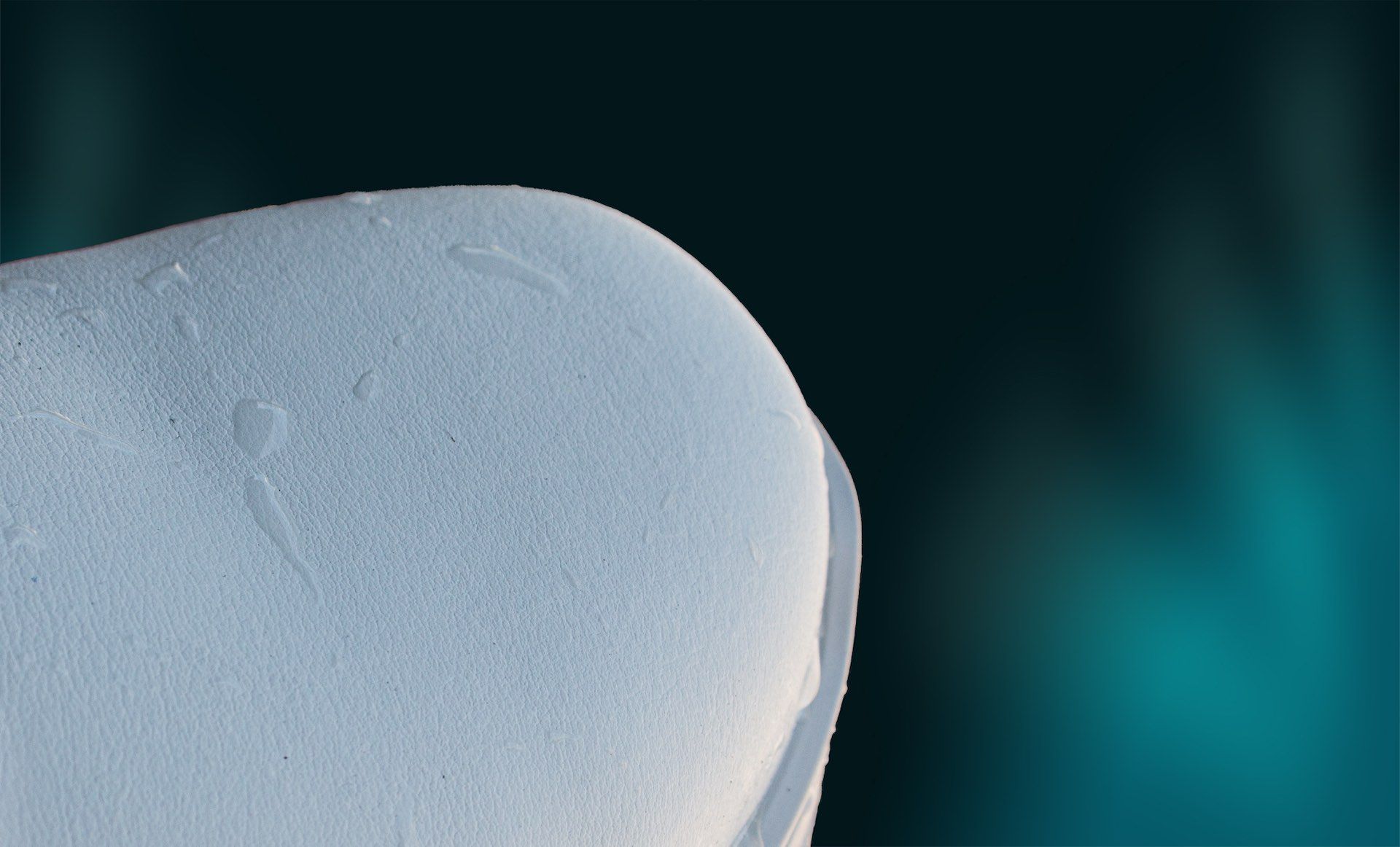

- Insole: Memory open-cell polyurethane, anatomical, extra comfort

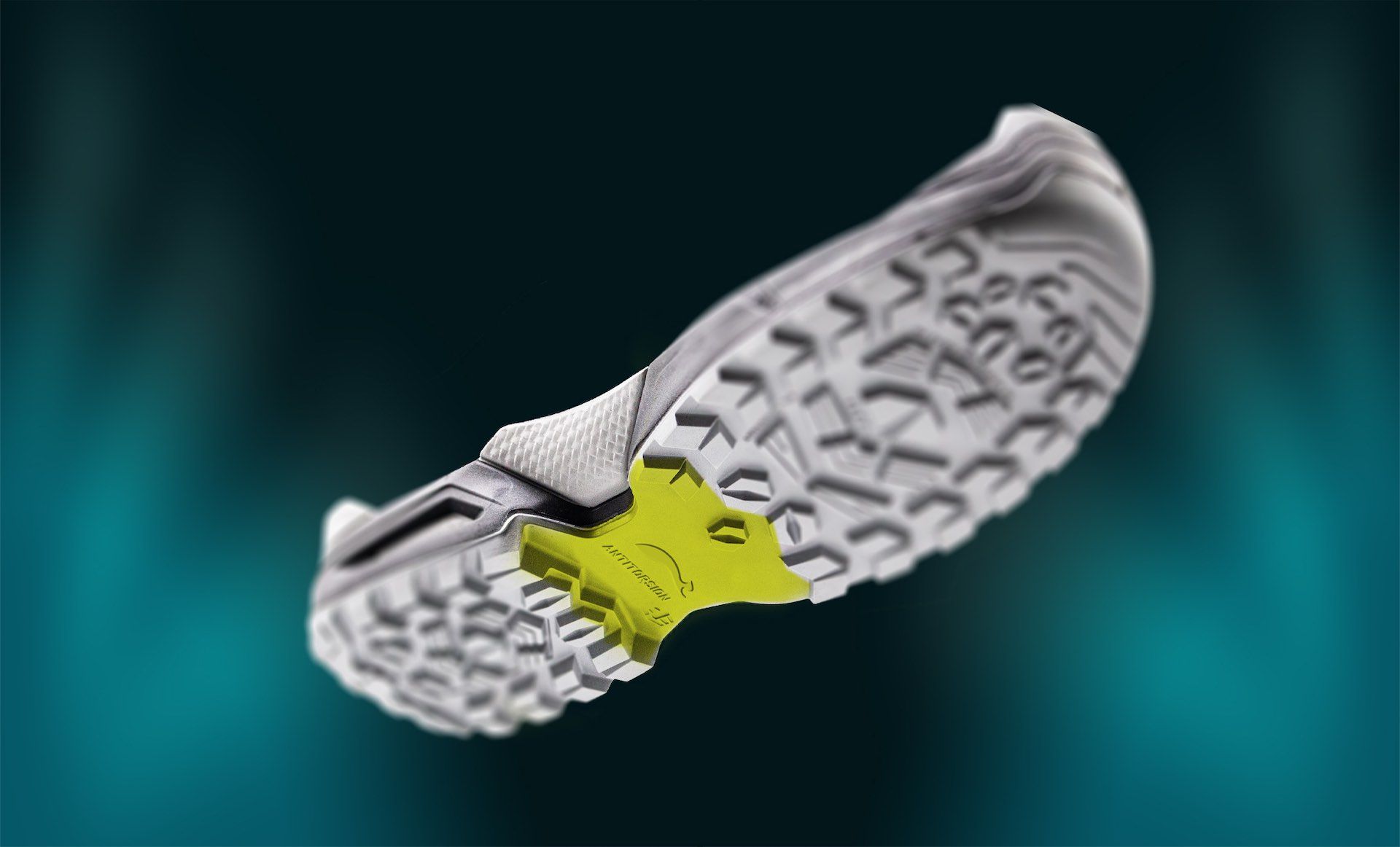

- Sole: PU/Outsole, PU/Midsole, PU/Upper sole

- Other: Esd, Anti-torsion sole shank, Chemical Resistant, Washable 40° (by hand and soap)

Description and further information

Highly perspiring and abrasion resistant fabric lining.

COMPLETELY METAL FREE SHOE

TOECAP 200J polymeric composite non-thermic according to EN 22568

SOLE 3HYBRID three-densities polyurethane antistatic, resistant to hydrolysis ISO 5423:92, to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

ANTI TORSION insert in the sole to assure stability on uneven ground

MEMORY INSOLE three-materials extra comfort insole, with soft latex Memory cushion, ensuring no stress in heel zone and resistant to body pressure.

Perspiring, removable, anatomic, absorbing, antistatic and anti-bacterial and ESD.

Footwear meets the requirement in accordance with IEC 61340-4-3:2017 (IEC 61340-5-1:2016) for electrical resistance ESD.

FO sole resistance to hydrocarbons

SR sole resistance against slipping

Size 36-47 Shoe weight Sz 42 gr. 425

Size guide

| EUROPA | UK | US | MILLIMETERS | INCHES |

|---|---|---|---|---|

35 | 2,5 | 3,5 | 225 | 8,9 |

36 | 3 | 4 | 232,5 | 9,2 |

37 | 4 | 5 | 240 | 9,5 |

38 | 5 | 6 | 247,5 | 9,7 |

39 | 6 | 7 | 255 | 10 |

40 | 6,5 | 7,5 | 262,5 | 10,3 |

41 | 7 | 8 | 270 | 10,6 |

42 | 8 | 9 | 277,5 | 10,9 |

43 | 9 | 10 | 285 | 11,2 |

44 | 10 | 11 | 292,5 | 11,5 |

45 | 10,5 | 11,5 | 300 | 11,8 |

46 | 11 | 12 | 307,5 | 12,1 |

47 | 12 | 13 | 315 | 12,4 |

48 | 13 | 14 | 322,5 | 12,7 |

49 | 14 | 15 | 330 | 13 |

ANTI-SLIP RESULTS

Forward Heel

(heel slip 7°)

Backward heel

(heel slip 7°)

Forward Heel

(heel slip 7°)

Backward heel

(heel slip 7°)

Recommended areas of use

Certifications applied

Certifications

Certifications

Certifications

Certifications

The upper material was also tested in the laboratory to determine chemical resistance according to a procedure similar to EN 13832-3:2018. Specifically, black MICROWASH was tested for resistance to: K. White MICROWASH was tested for resistance to: N, P, R, K, NaCl 37%.

Legend: (K)= Sodium Hydroxide 40%; (N)= Acetic Acid 99% (N), (P)=Hydrogen Peroxide (30%), (R)=Sodium Hypochlorite (13+-1%) of Active Chloride, (NaCl)= Sodium Chloride 37%

Certifications

Certifications

Certifications

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

Microwash is a highly breathable microfiber material designed to provide comfort and hygiene in industries such as food and healthcare, and to facilitate necessary cleaning. Its breathable polyurethane finish gives it a full-grain leather appearance while combining lightness and durability. Compared to natural leather, microfiber is 40% lighter, reducing fatigue even during long shifts. Another key feature is that it does not yellow when exposed to sunlight.

Technical materials

The Anti Torsion system uses a thermoplastic shank designed to increase stability on irregular and wet surfaces. Unlike standard shanks, it flexes with the foot’s natural motion, reducing the risk of twists and falls. Ideal for outdoor work, especially in construction, where surface control is critical.

Technical materials

Three to Be® - Tripla Densità Iniettata technology represents one of the most advanced results of our R&D efforts. Patented by Giasco, it integrates three entirely polyurethane-injected sole layers to optimize safety shoe performance in terms of comfort, stability, and slip resistance.