Three to be™ - Triple Density Injection

3 layers, 3 benefits, one lifestyle

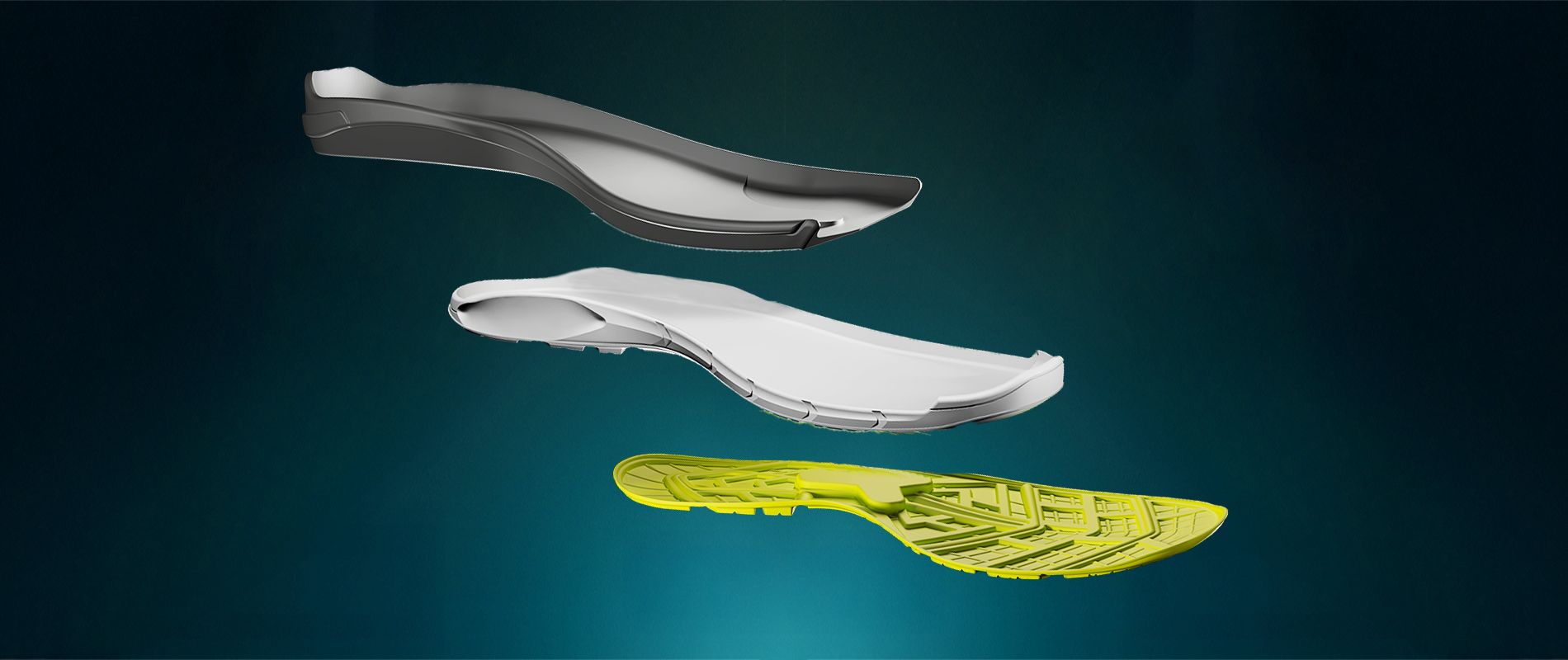

The Three to Be™ Triple Injected Density technology represents one of the most advanced results of our research and development activity. It is a patented solution by Giasco that integrates three different sole layers, entirely injected in polyurethane, with the goal of improving the performance of safety footwear in every aspect: comfort, stability, and slip resistance.

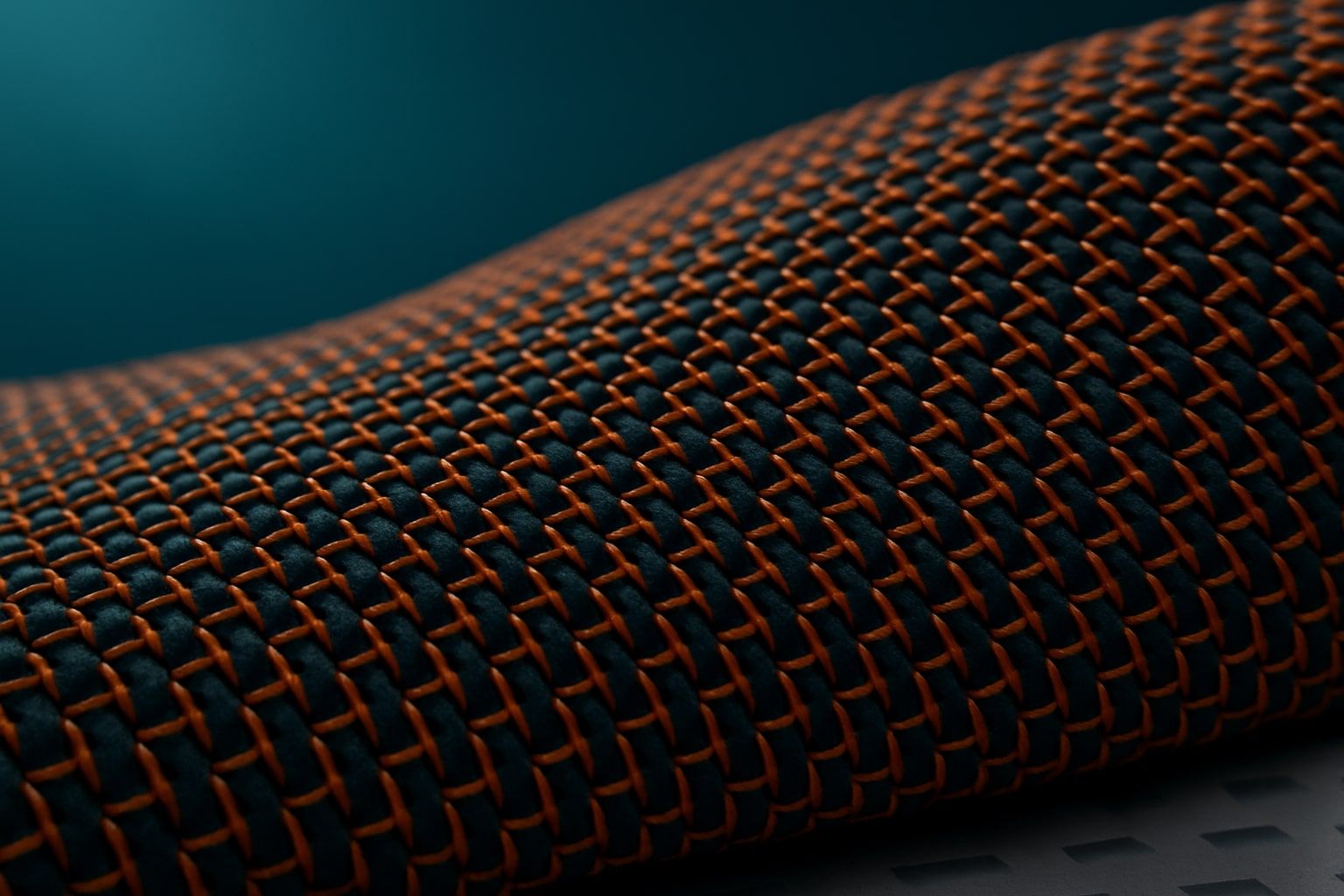

The combination of these three different sections, in addition to offering footwear with excellent performance in terms of softness, stability, and anti-slip properties, ensures an innovative play of colors. In fact, the use of more color combinations enhances the uniqueness and style of the model, while also increasing the possible outfit combinations.

Three-density structure: how does it work?

Technical composition of the sole

1

2

3

1

Soft and smooth

upper sole

Made with ultra-low-density expanded polyurethane, it guarantees superior cushioning, ideal for reducing fatigue even after many hours on your feet. Its elasticity allows for a gradual and natural energy return.

2

Stabilizing midsole

Made with tougher and more rigid polyurethane, this sole section provides structural support to the foot. It increases lateral stability and reduces the risk of twisting on uneven surfaces.

3

Durable and

slip-resistant outsole

The part in contact with the ground is made of a high-density polyurethane compound, designed to resist wear and maximize grip, even on oily or wet surfaces.

| Glued sole | Single-density sole | dual-density sole | tri-density sole THREE TO BE | |

|---|---|---|---|---|

Slip resistance | ||||

Wear resistance | ||||

Memory material for foot comfort |

Three to be heroes

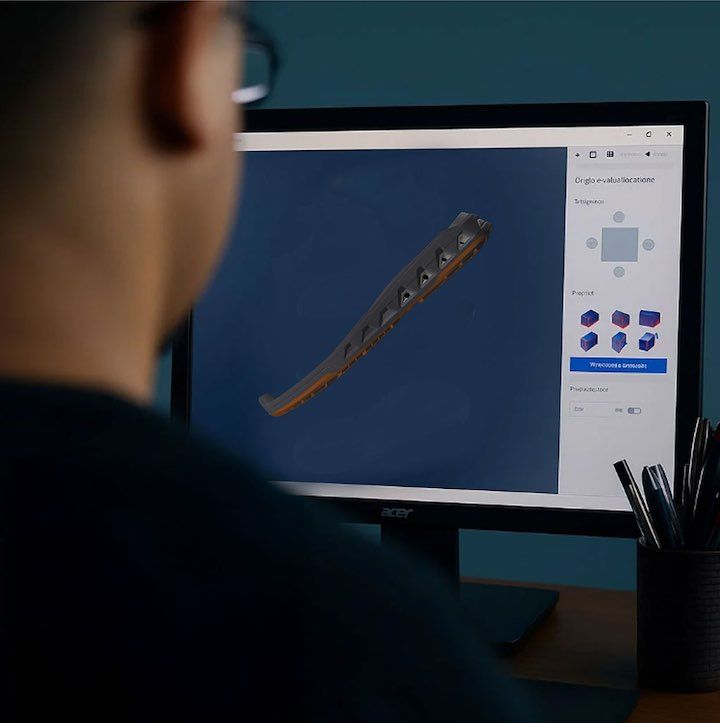

A project born from the analysis of working postures

- Shock absorption capacity

- Slip resistance (SRC)

- Structural and torsional stability

- Material durability

{{ nbHits }} available products

{{ nbHits }} available products