SOLDADOR S3 FO SR

CE EN ISO 20345:2022

AC880BSP

Ankle safety shoe

39-47

Description

Description and further information

High safety shoe, water-resistant WPA leather thickness 1,8-2,0 mm.

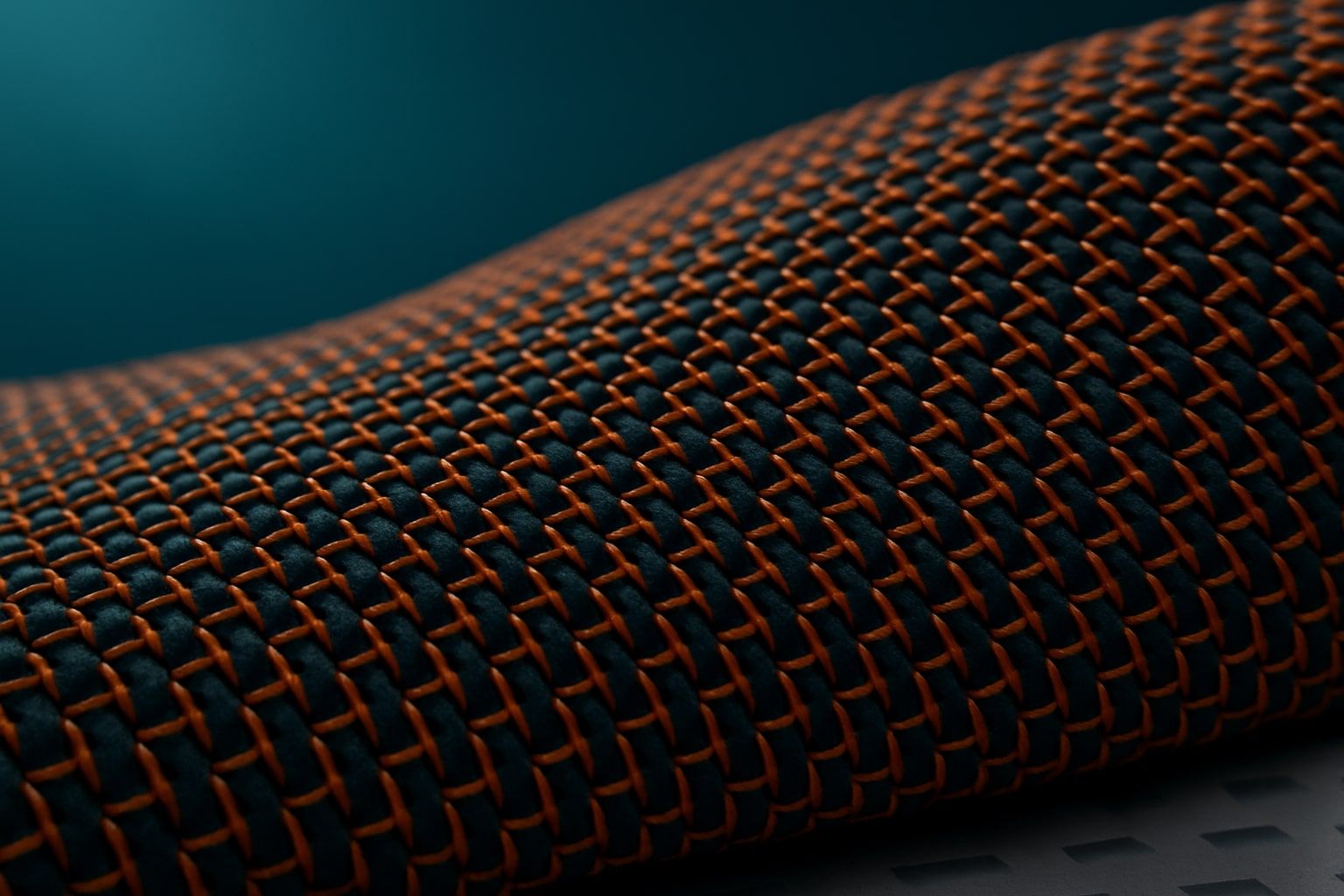

Perspiring and abrasion resistant fabric lining.

High visibility fabric insert. Lined and padded tongue.

Shoe with dross protective leather cover tongue and side closing by click buckle.

TOECAP 200J polymeric composite non-thermic according to EN 22568

MIDSOLE flexible antiperforation composite fabric according to EN 22568

SOLE ACTION bidensity polyurethane antistatic, resistant to hydrolysis ISO 5423:92, to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

INSOLE 4001, Comfort insole, perspiring, removable, anatomic, absorbing, antistatic ed antibacterial. Electrical resistance: the values found prove that this insole is ESD

FO sole resistance to hydrocarbons

SR sole resistance against slipping

Size 39-47 Shoe weight Sz 42 gr. 635

Perspiring and abrasion resistant fabric lining.

High visibility fabric insert. Lined and padded tongue.

Shoe with dross protective leather cover tongue and side closing by click buckle.

TOECAP 200J polymeric composite non-thermic according to EN 22568

MIDSOLE flexible antiperforation composite fabric according to EN 22568

SOLE ACTION bidensity polyurethane antistatic, resistant to hydrolysis ISO 5423:92, to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

INSOLE 4001, Comfort insole, perspiring, removable, anatomic, absorbing, antistatic ed antibacterial. Electrical resistance: the values found prove that this insole is ESD

FO sole resistance to hydrocarbons

SR sole resistance against slipping

Size 39-47 Shoe weight Sz 42 gr. 635

Size guide

Size guide

Comparison table of measurements

| EUROPA | UK | US | MILLIMETERS | INCHES |

|---|---|---|---|---|

35 | 2,5 | 3,5 | 225 | 8,9 |

36 | 3 | 4 | 232,5 | 9,2 |

37 | 4 | 5 | 240 | 9,5 |

38 | 5 | 6 | 247,5 | 9,7 |

39 | 6 | 7 | 255 | 10 |

40 | 6,5 | 7,5 | 262,5 | 10,3 |

41 | 7 | 8 | 270 | 10,6 |

42 | 8 | 9 | 277,5 | 10,9 |

43 | 9 | 10 | 285 | 11,2 |

44 | 10 | 11 | 292,5 | 11,5 |

45 | 10,5 | 11,5 | 300 | 11,8 |

46 | 11 | 12 | 307,5 | 12,1 |

47 | 12 | 13 | 315 | 12,4 |

48 | 13 | 14 | 322,5 | 12,7 |

49 | 14 | 15 | 330 | 13 |

See anti-slip results

ANTI-SLIP RESULTS

Anti-slip performance testing

Ceramic tile floor with NaLS

Forward heel

(heel slip 7°)

≥ 0.31

≥ 0.43

Backward heel

(heel slip 7°)

≥ 0.36

≥ 0.48

Ceramic tile floor with glycerin

Forward heel

(heel slip 7°)

≥ 0.19

≥ 0.31

Backward heel

(heel slip 7°)

≥ 0.22

≥ 0.26

SRA Ceramic + Nails

Flat

≥ 0.32

≥ 0.37

Heel

≥ 0.28

≥ 0.33

SRB Steel + Glicerol

Flat

≥ 0.18

≥ 0.22

Heel

≥ 0.13

≥ 0.24

Recommended areas of use

Construction and Building Sites

Metal and Wood Carpentry

Welding

Certifications applied

Heel Energy Absorption

Certifications

Heel Energy Absorption

Footwear with energy absorption in the heel to reduce impact while walking. Enhances comfort and protects joints in demanding work environments.

Antistatic Footwear

Certifications

Antistatic Footwear

Antistatic footwear designed to dissipate electrostatic charges, protecting the operator and sensitive devices. Ideal for industrial environments and electronic labs. Electrical resistance range from 0.1 MΩ to 1000 MΩ.

Hydrocarbon Resistance

Certifications

Hydrocarbon Resistance

Footwear resistant to hydrocarbons, designed to maintain the properties of the sole when in contact with oils and fuels. Ideal for industrial environments and workshops.

Slip Resistance (mandatory ceramic-Nals test)

Certifications

Slip Resistance (mandatory ceramic-Nals test)

According to EN ISO 20345:2022, slip resistance is a mandatory requirement and is tested on a ceramic surface contaminated with sodium lauryl sulfate (NaLS) solution. This test, stricter than previous versions, simulates real slipping conditions and ensures that all certified safety footwear provides a minimum level of grip. The SRA, SRB, and SRC classifications have been removed in the new regulation, making the NaLS ceramic test the standard.

Technical materials

High Visibility

Technical materials

High Visibility

High-visibility footwear with reflective inserts for greater safety in low-light conditions. Ideal for night work or high-risk environments.

Extreme Lightness

Technical materials

Extreme Lightness

This footwear uses a combination of innovative materials that minimize the weight of the work shoe, thus maximizing comfort and conserving energy at the end of the day.

Steel Plate

Technical materials

Steel Plate

Steel plate inserted in the sole to ensure puncture protection, maintaining resistance and durability in demanding work environments.

Mondo Point 11

Technical materials

Mondo Point 11

Mondo Point is an international standard indicating the type of fit of a particular shoe. In terms of fit, Mondo Point 11 indicates a wide, roomy, and comfortable shoe for the foot.

200J Composite Toecap

Technical materials

200J Composite Toecap

Composite toe cap resistant to impacts up to 200 Joules, lightweight and metal-free, ideal for safely protecting the toes without adding weight to the shoe. Unlike other materials, composite offers several advantages: non-thermal (does not transmit heat), non-magnetic (not detected by metal detectors), and shape-memory (in case of compression, it returns to its original state, freeing the toes).

Slip Resistance (optional glycerin test)

Technical materials

Slip Resistance (optional glycerin test)

The slip-resistant sole features a special compound and tread pattern designed to maximize grip on wet or slippery surfaces, improving safety on the job.