MICROWASH CHEMICAL RESISTANCE

Safety in every workplace is always a top priority; this means not only safe environments and safety devices, but also comfortable workplaces and PPE that is comfortable, practical to use and durable.

In particular, combining safety and comfort in the design of PPE is not an option; this is why the Giasco Research and Development team carefully studies and selects the materials used to make soles and uppers, thus offering the best performance for the sector and working environment for which they are intended.

For example, breathable and lightweight microfibre fabrics that are resistant and washable; non-slip and shock-absorbing soles or, conversely, thick and heavy, water-repellent and abrasion-resistant materials.

In particular, for the medical-hospital environment and the food industry, the fabrics selected and used for the outside of the upper are tested for resistance to detergents and disinfectants.

For these sectors, Giasco has selected the MICROWASH fabric.

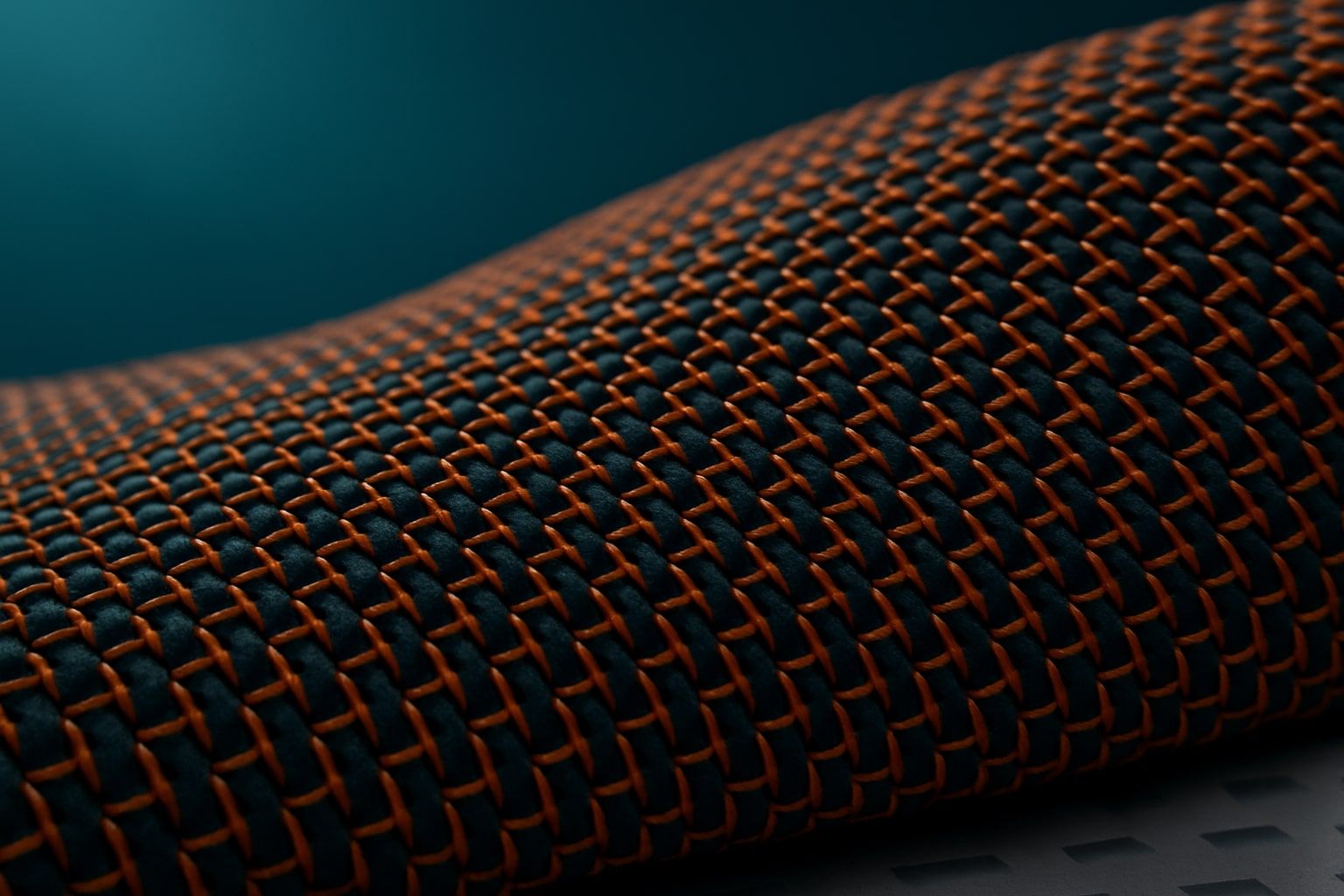

MICROWASH fabric is a chrome-free microfibre that guarantees breathability, lightness and protection from acids and aggressive products such as oleic acid, detergents and disinfectants.

Giasco's MICROWASH safety footwear is designed to offer users protection and maximum comfort throughout the day.

Furthermore, the finish of this breathable polyurethane microfibre fabric gives it the appearance of full-grain leather, but with a weight 40% lower than natural leather.

The footwear is hand washable with water at 40°C and neutral soap.

Giasco safety shoes in MICROWASH are available in two colours:

WHITE:

Laboratory tests to determine the chemical resistance (N, P, R, K, NaCl 37%)* of the WHITE upper material according to the EN 13832-3:2018 method.

Bergen EVO Line 3Move

Ustica Line 3Hybrid, Zante Line 3Hybrid, Maui Line 3Hybrid

Professional Eagle

Baltic Line Kube, Iceberg Line Kube, Constanta Line Kube, Helsinki Line Kube

BLACK:

Laboratory tests carried out on black MICROWASH to determine the chemical resistance (K)* of the BLACK upper material according to the EN 13832-3:2018 method.

Arendal EVO 3Move Line

Corfù 3Hybrid Line

Trivor 3Cross Line and Aneto 3Cross Line

Malmo Professional Line

Medina Kube Line, Free Kube Line

Cienzo 3Run Line, Buran 3Run Line

* chemical resistance test using a method similar to EN 13832-3:2018

K = sodium hydroxide 40%

N = acetic acid 99%

P = hydrogen peroxide 30%

R = sodium hypochlorite (13 ± 1) % active chloride

NaCl 37% = sodium chloride 37%