FREE SB FO A E

CE UNI EN ISO 20345:2012 SRC ESD

KU007O

Safety clog

36-47

Description

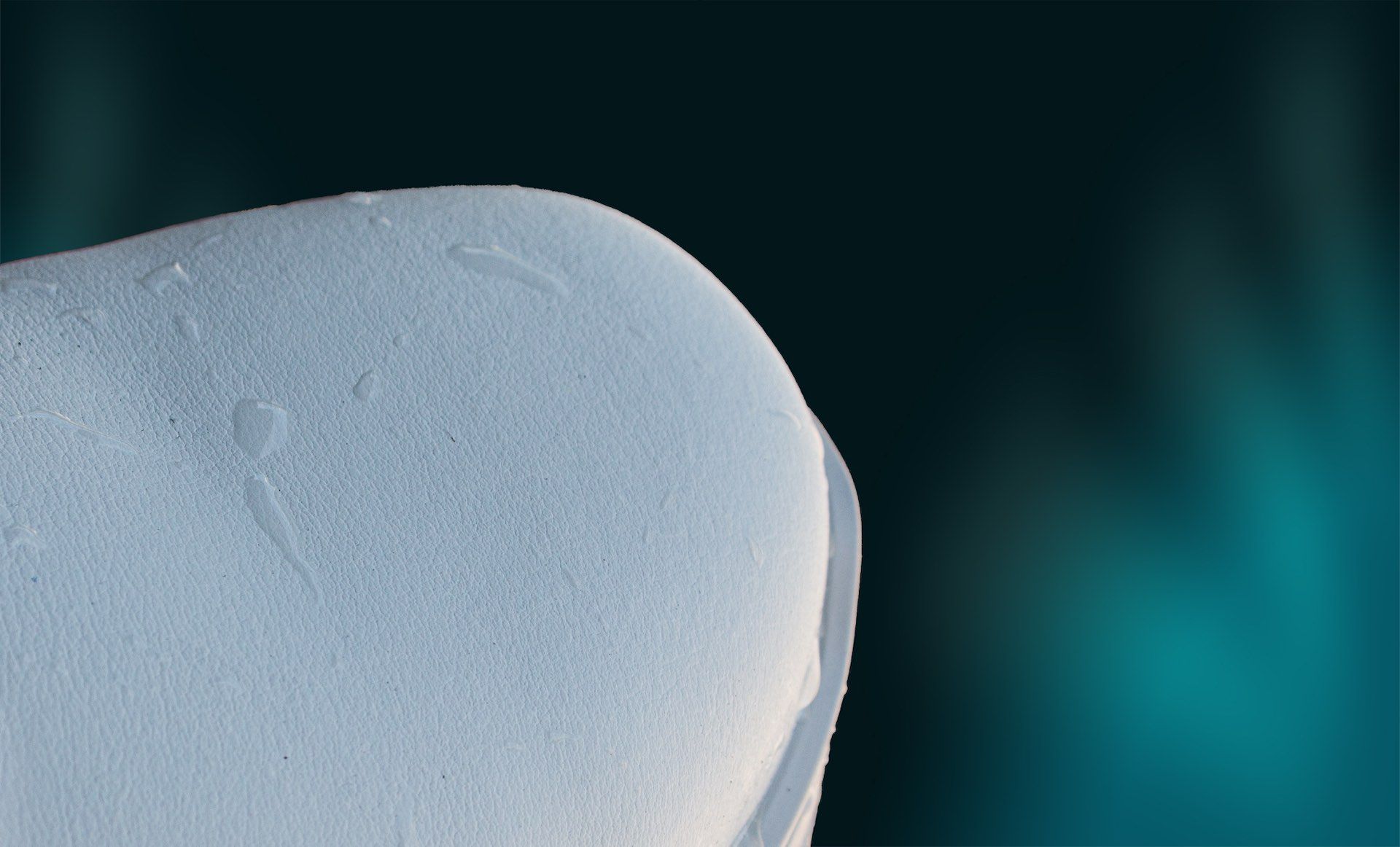

- Toecap: 200J polymeric composite non-thermic

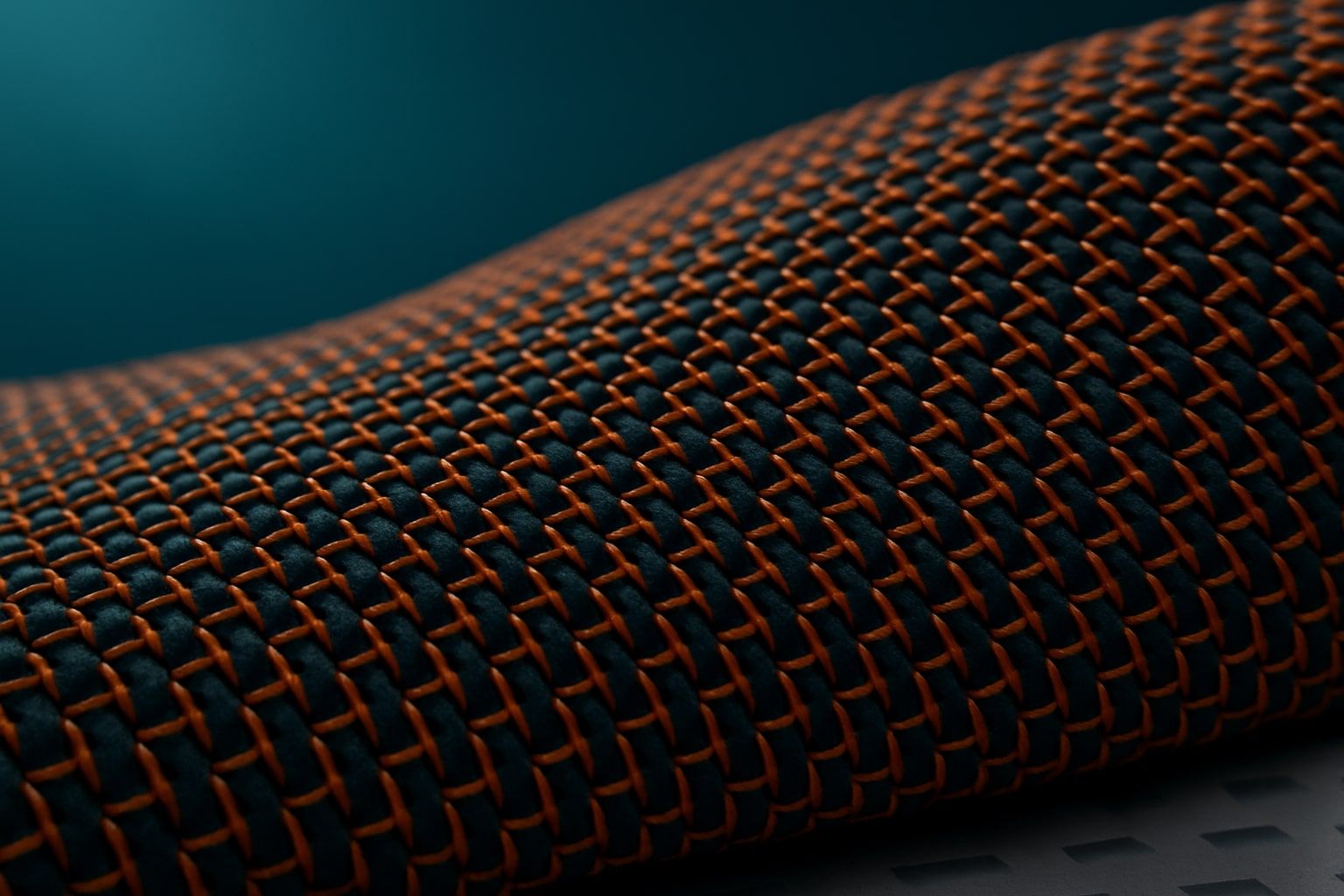

- Upper: Microfiber Microwash 1,8-2,0 mm

- Insole: Relax open-cell polyurethane extra comfort, anatomical

- Sole: PU/Outsole, PU/Midsole

- Other: Esd, Chemical Resistant, Washable 40° (by hand and soap)

Description and further information

Safety Sabot, MICROWASH thickness 1,8 – 2,0 mm.

Highly perspiring and abrasion resistant fabric lining.

Padded collar. Revolving belt.

TOECAP 200J polymeric composite non-thermic according to EN 12568

SOLE KUBE bidensity polyurethane antistatic, resistant to hydrolysis ISO 5423:92, to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

INSOLE 5000, three-materials extracomfort: perspiring, removable, anatomic, absorbing, ESD and anti-bacterial

The shoe satisfies the requirement according to the norm IEC 61340-4-3:2017 (IEC 61340-5-1:2016) for the electrical resistance ESD

FO sole resistance to hydrocarbons

A antistatic footwear

E energy absorption of seat region

THIS PRODUCT COMPLIES WITH THE REQUIREMENTS OF THE STANDARD ASTM F2413-24:

Impact resistant footwear (I)

Compression resistant footwear (C)

Slip Resistance (SRO)

Size 36-47 Shoe weight Sz 42 gr. 425

Highly perspiring and abrasion resistant fabric lining.

Padded collar. Revolving belt.

TOECAP 200J polymeric composite non-thermic according to EN 12568

SOLE KUBE bidensity polyurethane antistatic, resistant to hydrolysis ISO 5423:92, to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

INSOLE 5000, three-materials extracomfort: perspiring, removable, anatomic, absorbing, ESD and anti-bacterial

The shoe satisfies the requirement according to the norm IEC 61340-4-3:2017 (IEC 61340-5-1:2016) for the electrical resistance ESD

FO sole resistance to hydrocarbons

A antistatic footwear

E energy absorption of seat region

THIS PRODUCT COMPLIES WITH THE REQUIREMENTS OF THE STANDARD ASTM F2413-24:

Impact resistant footwear (I)

Compression resistant footwear (C)

Slip Resistance (SRO)

Size 36-47 Shoe weight Sz 42 gr. 425

Size guide

Size guide

Comparison table of measurements

| EUROPA | UK | US | MILLIMETERS | INCHES |

|---|---|---|---|---|

35 | 2,5 | 3,5 | 225 | 8,9 |

36 | 3 | 4 | 232,5 | 9,2 |

37 | 4 | 5 | 240 | 9,5 |

38 | 5 | 6 | 247,5 | 9,7 |

39 | 6 | 7 | 255 | 10 |

40 | 6,5 | 7,5 | 262,5 | 10,3 |

41 | 7 | 8 | 270 | 10,6 |

42 | 8 | 9 | 277,5 | 10,9 |

43 | 9 | 10 | 285 | 11,2 |

44 | 10 | 11 | 292,5 | 11,5 |

45 | 10,5 | 11,5 | 300 | 11,8 |

46 | 11 | 12 | 307,5 | 12,1 |

47 | 12 | 13 | 315 | 12,4 |

48 | 13 | 14 | 322,5 | 12,7 |

49 | 14 | 15 | 330 | 13 |

See anti-slip results

ANTI-SLIP RESULTS

Anti-slip performance testing

Ceramic tile floor with NaLS

Forward heel

(heel slip 7°)

≥ 0.31

≥ 0.56

Backward heel

(heel slip 7°)

≥ 0.36

≥ 0.45

Ceramic tile floor with glycerin

Forward heel

(heel slip 7°)

≥ 0.19

≥ 0.35

Backward heel

(heel slip 7°)

≥ 0.22

≥ 0.35

SRA Ceramic + Nails

Flat

≥ 0.32

≥ 0.39

Heel

≥ 0.28

≥ 0.37

SRB Steel + Glicerol

Flat

≥ 0.18

≥ 0.30

Heel

≥ 0.13

≥ 0.20

Recommended areas of use

ESD Area

Food, Hospital and Cleaning

Hotels, Restaurants and Catering

Certifications applied

Heel Energy Absorption

Certifications

Heel Energy Absorption

Footwear with energy absorption in the heel to reduce impact while walking. Enhances comfort and protects joints in demanding work environments.

ASTM F2413-24

Certifications

ASTM F2413-24

ASTM F2413-+E18:E6924 specifies the safety, performance, and protective requirements that safety footwear must meet according to U.S. standards.

Antistatic Footwear

Certifications

Antistatic Footwear

Antistatic footwear designed to dissipate electrostatic charges, protecting the operator and sensitive devices. Ideal for industrial environments and electronic labs. Electrical resistance range from 0.1 MΩ to 1000 MΩ.

Acid Resistance

Certifications

Acid Resistance

The sole of the following footwear has undergone laboratory testing for chemical resistance determination in accordance with a procedure similar to EN 13832-3:2018. Specifically, the sole was tested for resistance against the following substances: N, P, R, K, NaCl 37%.

The upper material was also tested in the laboratory to determine chemical resistance according to a procedure similar to EN 13832-3:2018. Specifically, black MICROWASH was tested for resistance to: K. White MICROWASH was tested for resistance to: N, P, R, K, NaCl 37%.

Legend: (K)= Sodium Hydroxide 40%; (N)= Acetic Acid 99% (N), (P)=Hydrogen Peroxide (30%), (R)=Sodium Hypochlorite (13+-1%) of Active Chloride, (NaCl)= Sodium Chloride 37%

The upper material was also tested in the laboratory to determine chemical resistance according to a procedure similar to EN 13832-3:2018. Specifically, black MICROWASH was tested for resistance to: K. White MICROWASH was tested for resistance to: N, P, R, K, NaCl 37%.

Legend: (K)= Sodium Hydroxide 40%; (N)= Acetic Acid 99% (N), (P)=Hydrogen Peroxide (30%), (R)=Sodium Hypochlorite (13+-1%) of Active Chloride, (NaCl)= Sodium Chloride 37%

Hydrocarbon Resistance

Certifications

Hydrocarbon Resistance

Footwear resistant to hydrocarbons, designed to maintain the properties of the sole when in contact with oils and fuels. Ideal for industrial environments and workshops.

Slip Resistant Sole

Certifications

Slip Resistant Sole

Slip-resistant sole with special compound and tread pattern designed to ensure maximum grip on wet or slippery surfaces. Improves safety during work.

Technical materials

ESD - Electrostatic Discharge

Technical materials

ESD - Electrostatic Discharge

ESD work shoes designed to dissipate electrostatic charges and protect sensitive electronic components. Ideal in environments such as electronic maintenance, automotive, laboratories, and many others. Electrical resistance range from 0.1 MΩ to 100 MΩ.

Extreme Lightness

Technical materials

Extreme Lightness

This footwear uses a combination of innovative materials that minimize the weight of the work shoe, thus maximizing comfort and conserving energy at the end of the day.

Mondo Point 11

Technical materials

Mondo Point 11

Mondo Point is an international standard indicating the type of fit of a particular shoe. In terms of fit, Mondo Point 11 indicates a wide, roomy, and comfortable shoe for the foot.

200J Composite Toecap

Technical materials

200J Composite Toecap

Composite toe cap resistant to impacts up to 200 Joules, lightweight and metal-free, ideal for safely protecting the toes without adding weight to the shoe. Unlike other materials, composite offers several advantages: non-thermal (does not transmit heat), non-magnetic (not detected by metal detectors), and shape-memory (in case of compression, it returns to its original state, freeing the toes).

Microwash

Technical materials

Microwash

Microwash is a highly breathable microfiber material designed to provide comfort and hygiene in industries such as food and healthcare, and to facilitate necessary cleaning. Its breathable polyurethane finish gives it a full-grain leather appearance while combining lightness and durability. Compared to natural leather, microfiber is 40% lighter, reducing fatigue even during long shifts. Another key feature is that it does not yellow when exposed to sunlight.