Description

- Toecap: 200J polymeric composite non-thermic

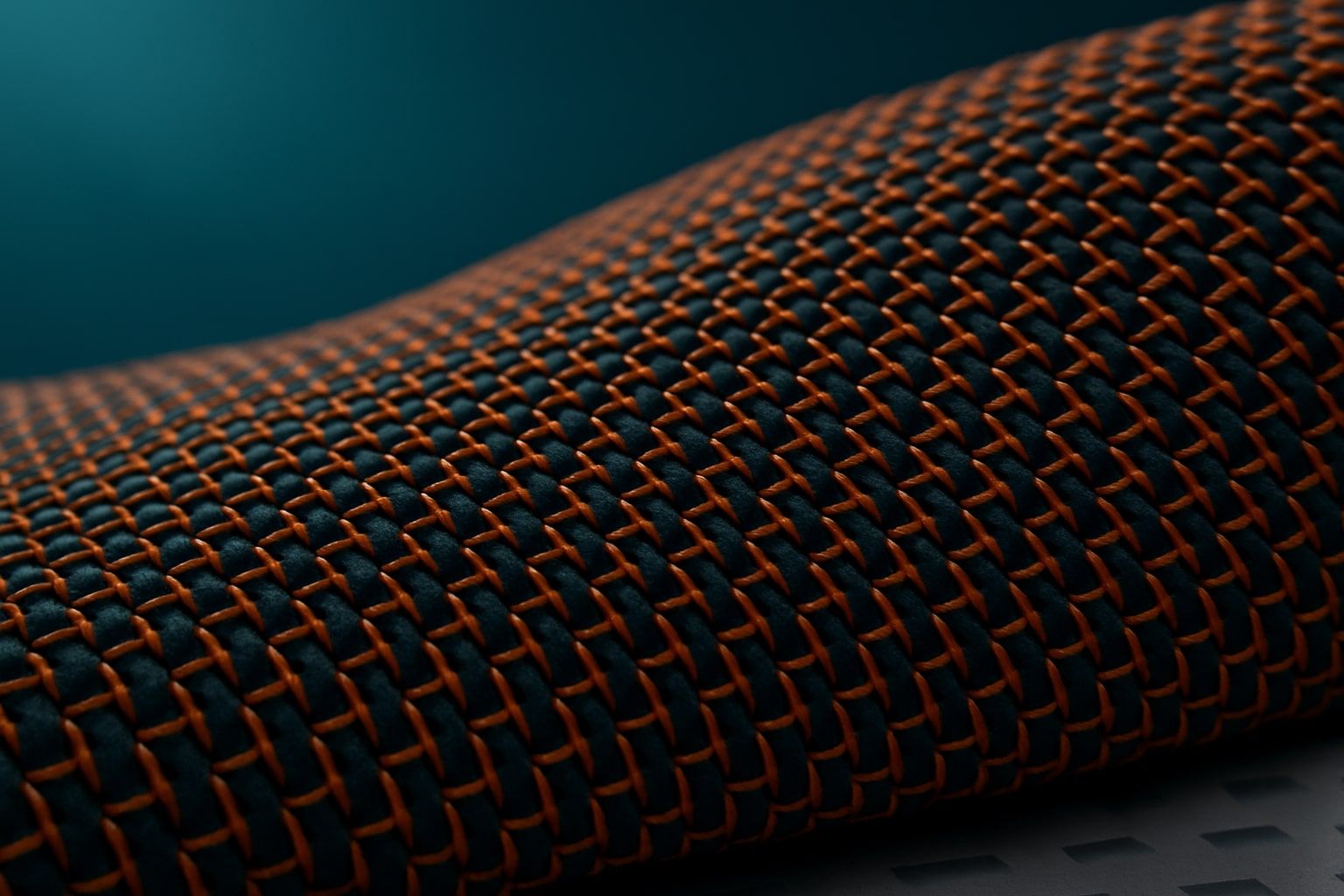

- Upper: Split pigmented leather Hydro 1,8-2,0 mm

- Midsole: PL certified antiperforation composite fabric

- Insole: Relax open-cell polyurethane extra comfort, anatomical

- Sole: PU/Outsole, PU/Midsole

- Other: Roof Grip

Description and further information

High safety shoe, back WRU leather thickness 1,8-2,0 mm.

Perspiring and abrasion resistant fabric lining.

Shoes with refracting fabric insert.

Soft, lined and padded tongue.

The shoe satisfies the requirements of slipping resistance on inclined roofs according to UNI 11583:2015

TOECAP 200J polymeric composite non-thermic according to EN 12568

MIDSOLE flexible antiperforation composite fabric according to EN 12568

SOLE KUBE bidensity polyurethane antistatic, resistant to hydrolysis ISO 5423:92,

to hydrocarbons and to abrasion, anti-shock and anti-slipping SRC

INSOLE 4001, Comfort insole, perspiring, removable, anatomic, absorbing, antistatic ed antibacterial. Electrical resistance: the values found prove that this insole is ESD

THIS PRODUCT COMPLIES WITH THE REQUIREMENTS OF THE STANDARD ASTM F2413-24:

Impact resistant footwear (I)

Compression resistant footwear (C)

Puncture Resistant Footwear (PR)

Slip Resistance (SRO)

Size 35-49 Shoe weight Sz 42 gr. 540

Size guide

| EUROPA | UK | US | MILLIMETERS | INCHES |

|---|---|---|---|---|

35 | 2,5 | 3,5 | 225 | 8,9 |

36 | 3 | 4 | 232,5 | 9,2 |

37 | 4 | 5 | 240 | 9,5 |

38 | 5 | 6 | 247,5 | 9,7 |

39 | 6 | 7 | 255 | 10 |

40 | 6,5 | 7,5 | 262,5 | 10,3 |

41 | 7 | 8 | 270 | 10,6 |

42 | 8 | 9 | 277,5 | 10,9 |

43 | 9 | 10 | 285 | 11,2 |

44 | 10 | 11 | 292,5 | 11,5 |

45 | 10,5 | 11,5 | 300 | 11,8 |

46 | 11 | 12 | 307,5 | 12,1 |

47 | 12 | 13 | 315 | 12,4 |

48 | 13 | 14 | 322,5 | 12,7 |

49 | 14 | 15 | 330 | 13 |

ANTI-SLIP RESULTS

Forward heel

(heel slip 7°)

Backward heel

(heel slip 7°)

Forward heel

(heel slip 7°)

Backward heel

(heel slip 7°)

Flat

Heel

Flat

Heel

Recommended areas of use

Certifications applied

Certifications

Certifications

Certifications

Certifications

Certifications

Certifications

Technical materials

Technical materials

Technical materials

Technical materials

Technical materials

High-resistance TEXTILE anti-perforation midsole. Protects the foot from penetration by dangerous and sharp objects. At the same time, it ensures maximum flexibility and lightness for the foot.

COMPOSITE toe cap resistant to impacts up to 200 Joules, lightweight and metal-free, ideal for safely protecting the toes without adding weight to the footwear.

Unlike other materials, composite offers several advantages: thermal insulation (does not transmit heat), non-magnetic (not detected by metal detectors), and memory (in case of compression, it returns to its original shape, leaving toes free).

Technical materials